This was a question posted recently on the “Shoe Repairer’s Forum”, asking why there isn’t an abundance of second hand machinery on the market considering the number of repairers shops to close in recent years.

This is a very good question. Where does one look for good quality secondhand machinery these days?

Perhaps a better question is with new machinery being available at very competitive prices, why do so many repairer’s still have a hankering for old, outdated machinery?

It would appear that a number of shoe repairers still believe that there is a ready supply of top quality secondhand machinery out there, which no doubt, will be small, quiet, barely used, running perfectly, available for a couple of hundred quid and with delivery thrown in. Or, as a worse case scenario they believe that they can pick-up a similar machine to the one purchased by their father 30-years ago, preferably at the same price!

Why is this? Is there another industry where a noticeable percentage of the participants actively seek to acquire the main money-making machine of their company from the industry equivalent of the rubbish tip?

If they can by some miracle obtain their bargain finishing machine what exactly have they acquired for their money?

- Almost certainly it will be at least a couple of decades old and been used on almost every day of those decades.

- The grubby outward appearance of the machine will be such that it would sit uncomfortably in a modern High Street shop.

- The motors, pullies, and bearings are likely to be on their last legs.

- The consumable items like cutters, brushes, pads and mops will be worn down to the nub.

- The machine may be noisy and produce plenty of dust.

- It may not comply with today’s more stringent Health and Safety directives.

There’s an old saying which would appear to be relevant at this point.

“Buy cheap – buy twice”.

Why suffer all these problems and dangers when the alternative is to invest in your business and purchase new machinery?

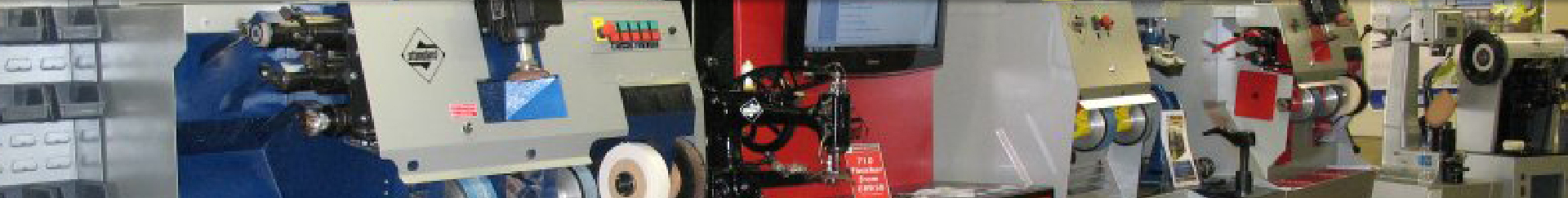

The advantages of taking this option over raiding a museum piece for your livelihood are numerous: -

Affordability

Prices of new finishers have nowhere near risen by the rate of inflation over the last 20 years.

Leasing

Let the machine earn the money to pay for itself whilst you take a leisurely 5-years to complete your payments.

Reliability

Peace of mind with a lengthy guarantee?

Specifications

Why use the specifications that were acceptable to another shoe-repairer a generation ago? Have the machine specified how you would like it to be with tooling to suit YOUR needs.

Colour

Don’t settle for a dust / rust coloured machine when you can have it the colour YOU want, at no extra charge. Why not match your machinery to your shop décor? If you don’t have a particular shop decor then think about doing this as it will invariably lead to a higher turnover.

Power Supply

If you are waiting for a pristine machine to fall into your lap specified to your electrical requirements (i.e. I or III phase) you could be waiting for a long time. Why not simply order a new machine engineered to YOUR power requirements?

Health & Safety

A new machine will be CE certified and have the latest extraction, along with lower noise levels.

Consumables And Parts

Will be readily available, which is important to consider. Imagine your horror when your wholesale merchant advises you that the length of band you are looking for ceased production in 1962! Alternatively the parts for your old machine are no longer made, or are only available as “specials” at equally “special” prices!