When the local GP needs to hunt out a replacement stethoscope does he buy a new one or look through the Lancet for a doctor selling a secondhand one? Does the airline company check out the local scrapyards when looking to replace their fleet or have new aircraft built? Would Manchester United call upon Bobby Charlton if Ronaldo injured himself taking one of his dives?

The shoe repair industry is by no means immune from the debate about buying old or new.

Everyone likes a bargain. You don’t mind picking up a cheap pair of sandals which last the two weeks of your holiday in Spain. Not so great when you pick up an old finishing machine to run your business and it breaks down after a fortnight, and the spare parts for it were last widely available during the Kennedy presidency.

Are new machines exorbitantly expensive and well beyond the means of the humble shoe repairer? Hardly. The price of new machinery has lagged well behind inflation over the past twenty years.

Today, new machinery can cost as little as 25% more than fully reconditioned machinery. For this relatively small additional cost the repairer benefits in many ways. Firstly, and most importantly, every part of the machine is brand new. This may seem an obvious statement, but think about it for a moment. Each and every component has been specifically and recently constructed to be put into YOUR new machine. There is nothing within the device which is being reused or reengineered; it is all being run for the first time. Buying a machine previously used by another repairer can be problematic as every repairer has their own way of working and their own view of maintenance. This can have a bearing on secondhand machines in particular.

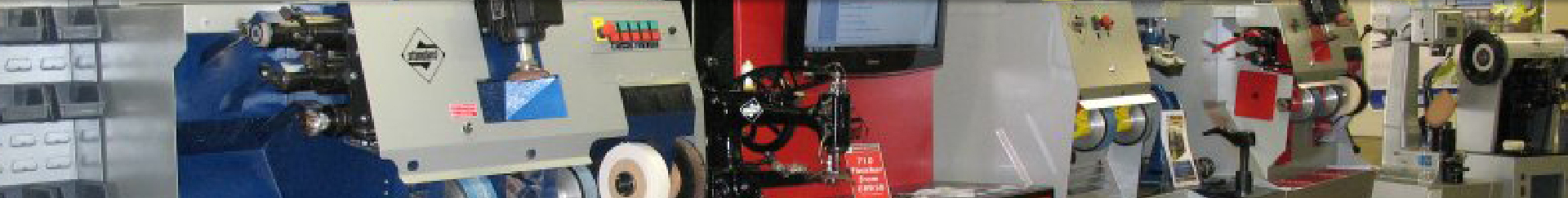

Obviously as the finisher is new it will be far more reliable than a machine which, even reconditioned to the highest possible standards, is still using any number of older components. What price for the peace of mind which comes from knowing your new machine will run well and have all the consumables and parts it requires available for years to come? With the average age of machinery being 12 years old before refurbishment, this should be a major consideration when buying.

Increasingly the shoe repairer needs to compete for every Pound spent on the high street, and investing in new machinery, along with modernising their shops will allow them to compete in an increasingly tight market. More often than not the shoe repairer is the sole or main breadwinner in a household. Surely it is sensible to think in the long term when seeking to secure the continuing viability of your business.